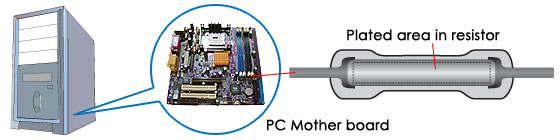

A wide range of plating types are used in the electronics industry. These include gold, electrolytic and electroless nickel, palladium nickel, tin, and ENIG plating. These plating techniques are used in the production of such products as hard disks, probe testers, PCBs, battery contacts and resistors.

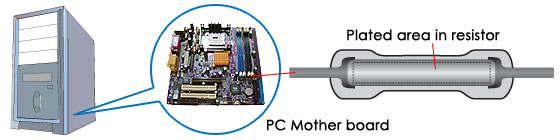

| Plating for Ceramic Resistor |

|

Multi-Layer Alloy Plating for functional resistive film. Superior Adhesion over Ceramics, Stable Plating Speed, Excellent Resistance Value

| Specifications |

| Size: |

1S,2S,3S,5S,12S |

| Substrate: |

Ceramic |

| Metallization: |

Ni-Cu Alloy |

| Thickness: |

6 - 30 µm |

| Technical Challenges |

| Multi-Layered Copper / Nickel Alloy Plating with High Adhesion and Resistance Properties. |

Plating on Resistor |

Please refer to the relevant pages

Nickel Plating, Copper Plating

|

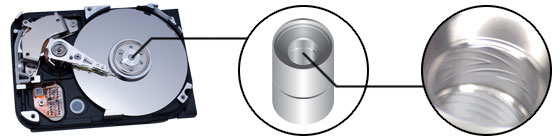

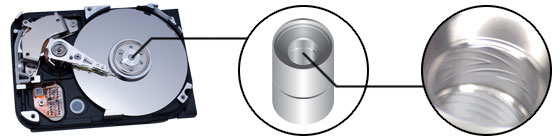

| Plating for Hydrodynamic Bearing |

|

Plating Done For Spindle Motor of Computer Hard Disks.

| Specifications |

| Size: |

0.85", 1.0", 1.8", 2.5", 3.5" |

| Substrate: |

Ceramic |

| Metallization: |

EN |

| Thickness: |

Controlled within 20nm |

| Technical Challenges |

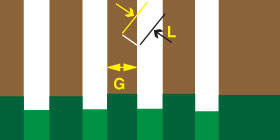

| Precise Plating Thickness Controlled in Nano-meter |

Plated Area |

Please refer to the relevant pages

Nickel Plating

|